The SDC‐9 culture is a pathogen‐free, non‐genetically altered microbial consortium capable of biologically degrading halogenated aliphatic pollutants including , 1,1,1‐TCA, 1,1,2‐TCA, 1,1‐DCA, 1,2‐DCA, 1,2‐DBE, TeCA, CT, CF, PCE, TCE, DCE, VC, and Freon 113 (1,2‐dichloro‐1,2‐difluoroethane), and also mixtures thereof. Molecular biological analyses of the SDC‐9 culture has demonstrated that the culture has at least four closely‐related strains of Dehalococcoides sp. bacteria which is the only bacterial genus known to degrade chlorinated ethenes completely to ethene. In addition, the culture contains other known pollutant degrading bacteria including Desulfitobacterium and Desulfovibrio strains.

It has now been successfully applied more than 3,000 times, and hundreds of thousands of liters have been delivered to sites throughout the United States.

Would you like a quote for your project or a sample of one of our zero valent iron products? We can help

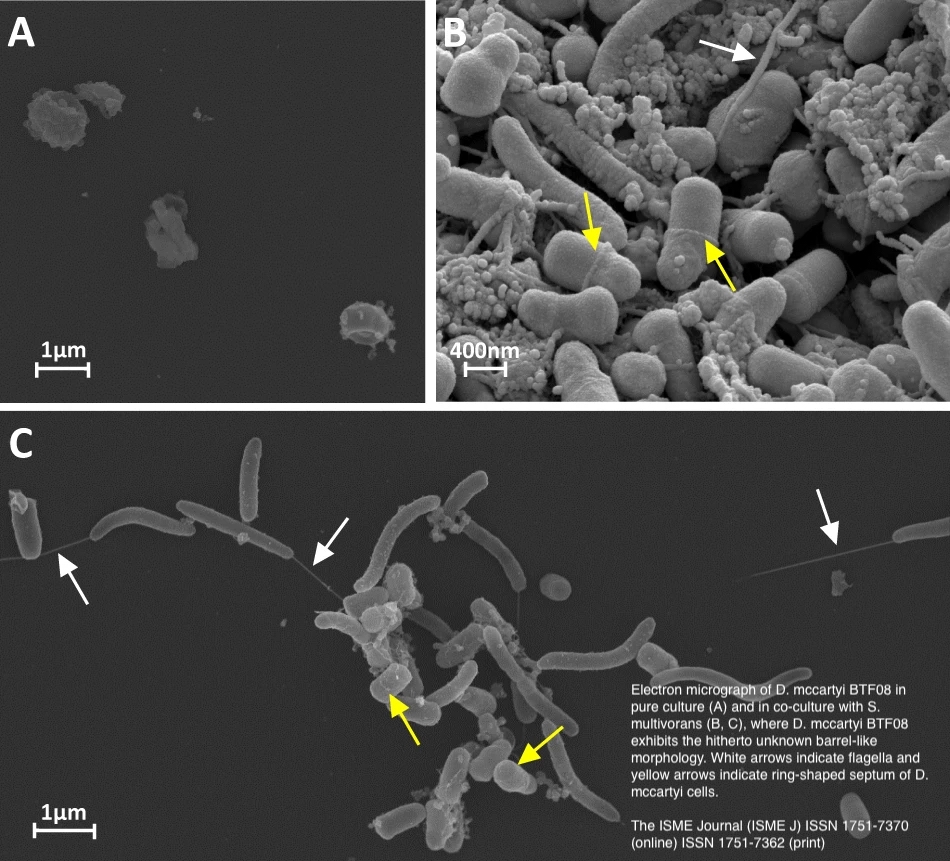

Electron micrograph of D. mccartyi BTF08 in pure culture (A) and in co-culture with S. multivorans (B, C), where D. mccartyi BTF08 exhibits the hitherto unknown barrel-like morphology. White arrows indicate flagella and yellow arrows indicate ring-shaped septum of D. mccartyi cells.

The ISME Journal (ISME J) ISSN 1751-7370 (online) ISSN 1751-7362 (print)

| Specification | Limit |

|---|---|

| Cell Count: | > 1 x 10^11 cells/liter |

Recommended dosage: | 1 x 10^7 cells/liter/injection |

| pH Value | 6-8 approx. |

| Packaging | 19 liter chilled canisters |

| Appearance | greenish and cloudy |

The optimal dosage of Dehalococcoides (DHC) culture in an aquifer for effective anaerobic bioremediation of chlorinated solvents (e.g., PCE, TCE, VC) depends on several factors, including:

Typical Dosage Range: The optimal dosage of DHC in an aquifer typically ranges from 10⁶ to 10⁸ cells per liter (cells/L) of groundwater or aquifer material. This range is based on field and laboratory studies for effective dechlorination of chlorinated ethenes (e.g., PCE, TCE, VC).

| BTEX-Benzene, toluene, ethylbenzene, xylenes |

| Tert Butyl Alcohol (TBA) |

| MTBE-Methyl tert-butyl-ether |

| GRO-Gasoline Range Organics |

| DRO-Disel Range Organics |

| ORO-Oil Range Organics |

| Styrene |

| Anthracene |

| Naphthalene |

| Phenanthrene |

| Pyrene Creosote and others |

| Chlorobenzenes |